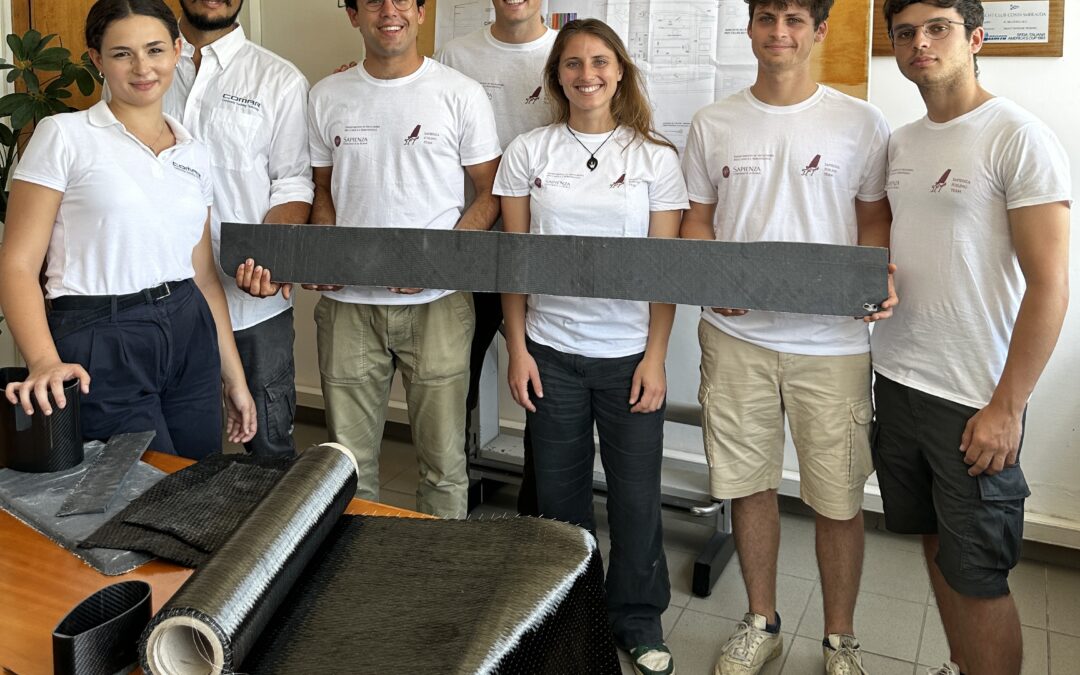

This week, at the Foiling SuMoth Challenge (FSMC), Federico Romeo and the Department of Mechanical and Aerospace Engineering at Sapienza University of Rome present the first phase of an ambitious project: to design, build, and sail the most sustainable and efficient foiling International Moth (IMCA) ever created. It’s an initiative in which Comar Yachts is directly involved, supporting the university team not only by sharing its technical know-how but also by supplying leftover materials recovered from the production of its catamarans, nearly 20 meters long and significantly larger than the 3.35-meter Moth the students are building. “At the Fiumicino shipyard, we found extremely interesting materials for our project,” says Romeo, the team leader. “The composite sheets, already manufactured and ready to be shaped, mostly come from bulkhead offcuts or the inner cutouts for portholes. Small pieces, when compared to a 65-foot catamaran, but perfect—and incredibly valuable—for our Moth.”

The same reuse philosophy was applied to the resin: the excess resin from boat production was recovered and made available to the team, in sufficient quantity to build many, if not all, of the prototype’s components. The same goes for the carbon fiber: both unidirectional and bidirectional offcuts have been repurposed as structural reinforcements, in compliance with competition rules that limit the use of carbon fiber to no more than two kilograms.

This collaboration with the Foiling Sailing Team is a concrete example of circular economy applied to the marine industry, where technology, innovation, and sustainability come together to give new life to materials that would otherwise be discarded.Let me know if you’d like an even more concise or promotional version for international media use.